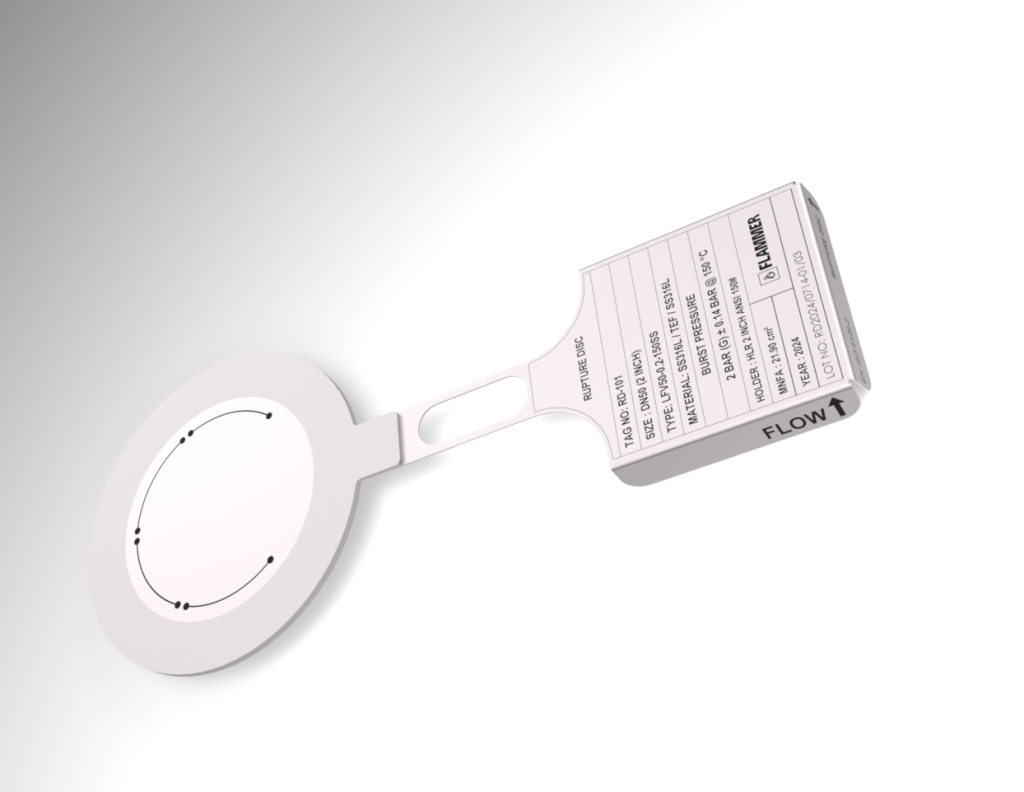

The LF Series Flat Composite Rupture Disc is designed to provide reliable overpressure protection in various industrial applications. This rupture disc features a flat, multi-layered design, offering precise and repeatable burst pressures while accommodating a wide range of operating conditions. Its composite structure allows it to handle both gaseous and liquid media, making it a versatile choice for many industries.

Consists of multiple layers of materials, offering enhanced durability and precision in burst pressure performance.

The flat configuration ensures uniform pressure distribution and consistent operation across the entire surface of the disc.

Prevents fragmentation upon bursting, ensuring the integrity of downstream equipment and maintaining safety.

Operates without needing vacuum support, withstanding full vacuum conditions.

Accommodates a variety of burst pressure requirements, making it suitable for different applications.

Capable of operating at high percentages of the burst pressure, ensuring reliable performance without premature failure.

Suitable for use with gases, liquids, and two-phase flows across various industries, including chemical processing, pharmaceuticals, and oil & gas.

Available in a range of materials, including Stainless Steel, Nickel, Monel, and Inconel, to meet specific application needs.

| Nominal Disc Size | Material | Burst Pressure Range (min) – psig (barg) @ 72°F (22°C) | Maximum Burst Pressure (psig) |

|---|---|---|---|

| 1″ | SS, Nickel, Monel | 10 – 30, 0.7 – 2.0 | 1500 |

| 25 mm | SS, Nickel, Monel | 0.7 – 30, 0.7 – 2.0 | 100 |

| 1-1/2″ | SS, Nickel, Monel | 10 – 28, 0.7 – 1.9 | 1500 |

| 40 mm | SS, Nickel, Monel | 0.7 – 28, 0.7 – 1.9 | 100 |

| 2″, 2.6″ | SS, Nickel, Monel | 10 – 25, 0.7 – 1.7 | 1500 |

| 50 mm, 65 mm | SS, Nickel, Monel | 10 – 25, 0.7 – 1.7 | 1500 |

| 80 mm | SS, Nickel, Monel | 0.7 – 25, 0.7 – 1.7 | 100 |

| 3″ | SS, Nickel, Monel | 10 – 20, 0.7 – 1.4 | 1500 |

| 4″ | SS, Nickel, Monel | 1 – 15, 1 – 1.0 | 750 |

| 100 mm | SS, Nickel, Monel | 15 – 15, 1 – 1.0 | 750 |

| 6″ | SS, Nickel, Monel | 1 – 10, 1 – 0.7 | 750 |

| 150 mm, 8″ | SS, Nickel, Monel | 1 – 10, 1 – 0.7 | 750 |

| 200 mm, 10″ | SS, Nickel, Monel | 1 – 10, 1 – 0.7 | 750 |

| 250 mm, 12″ | SS, Nickel, Monel | 1 – 10, 1 – 0.7 | 750 |

| 300 mm | SS, Nickel, Monel | 10 – 10, 0.7 – 0.7 | 750 |

Maximum Temperatures:

| Specified Burst Pressure Rating | Manufacturing Ranges | Burst Tolerance |

|---|---|---|

| 1.0 to below 5.0 | +/-0.50 | +/-0.50 |

| 5.0 to below 10.0 | +/-0.30 | +/-0.80 |

| 10.0 to below 15.0 | +/-0.60 | +/-1.30 |

| 15.0 to below 40.0 | +/-0.09 | +/-2.00 |

| Above 40 | +/-5% | +/-5% |

The BI Series Rupture Disc Indicator is a one-time-use burst sensor that can be installed to detect rupture disc activation in real-time. This explosion-proof sensor is suitable for use in hazardous environments, providing an additional layer of safety.

We’d love to hear from you! Whether you have a question about our products, need assistance, or want to discuss a project, our team is here to help. We value strong connections with our clients and partners, and we’re committed to providing exceptional service.