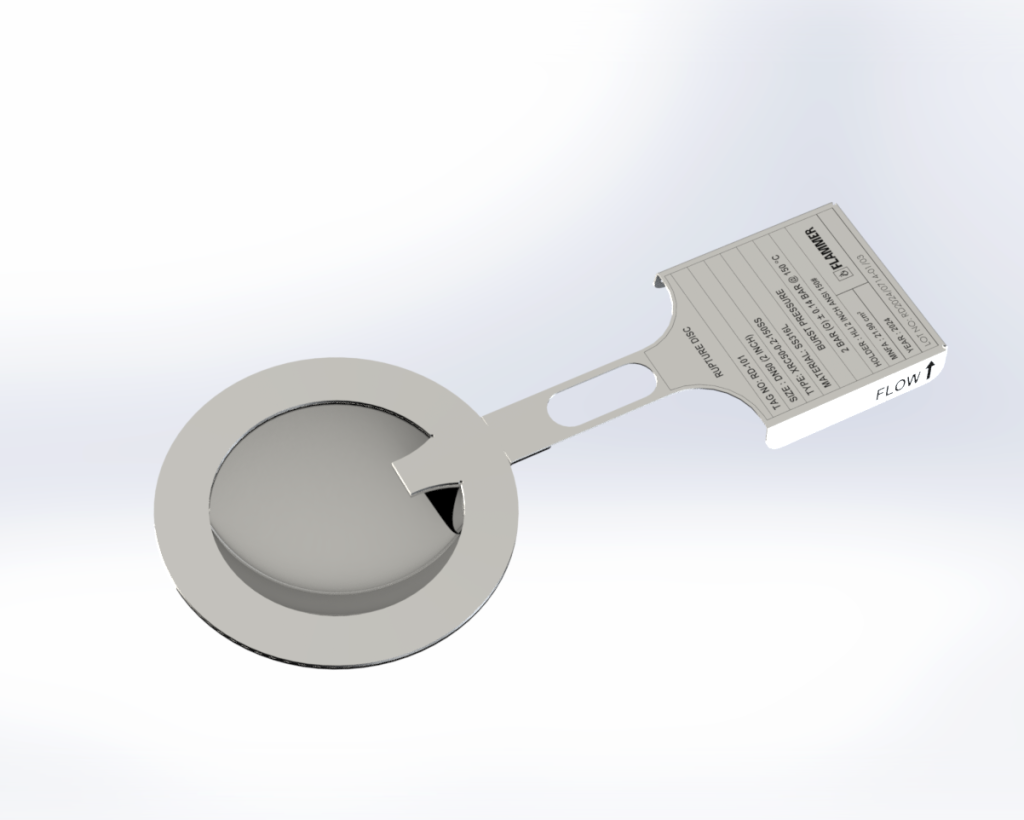

The Flammer XRC is a high-performance, reverse buckling metal rupture disc designed to ensure safety in pressure relief systems. Featuring a domed, solid metal construction, this rupture disc operates by reversing on overpressure. It opens by cutting along the teeth ring and groove, and its integral ring retains the central part of the disc to prevent fragmentation, enhancing safety.

Ideal for isolating safety relief valves.

Up to 95% of the marked burst pressure, offering long service life.

Suitable for liquid, gas, or two-phase systems.

Operates without needing vacuum support, withstanding full vacuum conditions.

Available in a wide range of standard and exotic materials, including SS316L, Hastelloy, Nickel, Inconel, Monel, and Tantalum.

Covers sizes from 25 mm (1 inch) to 150 mm (6 inches).

Multi-layer construction for corrosive materials and PTFE liners or coatings.

Can be delivered at short notice, including urgent sets of three rupture discs.

| Nominal Disc Size | Burst Pressure Range (min) – psig @ 72°F (22°C) | Burst Pressure Range (max) – psig @ 72°F (22°C) | Maximum Burst Pressure – psig (barg) |

|---|---|---|---|

| 1″, 1½” | 7 (0.5) | 22 (1.5) | 1500 (103) |

| 2″, 2½” | 7 (0.5) | 20 (1.4) | 1500 (103) |

| 3″, 4″ | 5 (0.3) | 17 (1.1) | 1500 (103) |

| 6″ | 5 (0.3) | 15 (1.0) | 1000 (69) |

| 8″ | 5 (0.3) | 15 (1.0) | 750 (52) |

| 10″ | 5 (0.3) | 15 (1.0) | 750 (52) |

| 12″ | 5 (0.3) | 15 (1.0) | 750 (52) |

| 16″ | 5 (0.3) | 15 (1.0) | 750 (52) |

| 20″ | 5 (0.3) | 15 (1.0) | 750 (52) |

| 24″ | 5 (0.3) | 15 (1.0) | 750 (52) |

| 200 mm | 7 (0.5) | 17 (1.1) | 1100 (76) |

| 250 mm | 7 (0.5) | 15 (1.0) | 1100 (76) |

| 300 mm | 7 (0.5) | 15 (1.0) | 750 (52) |

| Specified Burst Pressure Range – psig (barg) | Manufacturing Ranges (barg) | Burst Tolerance (barg) |

|---|---|---|

| 1.0 to below 5 | +/-0.5 | +/-5% |

| 5 to below 10 | +/-1.0 | +/-5% |

| 10 to below 15 | +/-1.5 | +/-5% |

| 15 to above 46 | +/-3.0 | +/-5% |

We’d love to hear from you! Whether you have a question about our products, need assistance, or want to discuss a project, our team is here to help. We value strong connections with our clients and partners, and we’re committed to providing exceptional service.